Enhancing Machining Accuracy with CNC Collet Chucks #

Collet chucks are fundamental tool-holding devices in machining, designed to secure cutting tools with consistent clamping force. By utilizing a collet and chuck body, these devices ensure that tools are held firmly, supporting high machining accuracy and repeatability. The precise control over clamping force contributes to stable and reliable machining operations.

As a manufacturer focused on precision and efficiency, Ann Way offers a diverse range of collet chucks tailored for various machining requirements.

Types of Collet Chucks Available #

Ann Way provides several types of collet chucks, each engineered for specific applications:

- ER Collet Chucks: Universally applied, these chucks are optimized for design, precision, and safety. They are suitable for clamping drills, reamers, end mills, and taps, making them among the most popular choices.

- Straight Shank ER Collet Chucks: These versatile chucks are ideal for clamping a variety of round shank tools, such as spot drills, drills, taps, and reamers. They can also serve as extended-length chucks when used with appropriate toolholders.

ER Spring Collet ChuckBT / NT Series

ER Spring Collet ChuckBT / NT Series

ER Spring Collet ChuckBT / NT Series

ER Spring Collet ChuckBT / NT Series

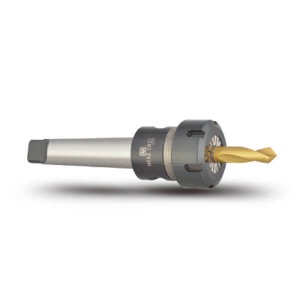

ER Morse Taper Shank - Tang TypeBT / NT Series

ER Morse Taper Shank - Tang TypeBT / NT Series

ER Morse Taper Shank - Draw Bolt TypeBT / NT Series

ER Morse Taper Shank - Draw Bolt TypeBT / NT Series

ER Straight Shank Collet ChuckBT / NT Series

ER Straight Shank Collet ChuckBT / NT Series

ER Straight Shank Collet Chuck - M TypeBT / NT Series

ER Straight Shank Collet Chuck - M TypeBT / NT Series

ER R8 Taper ShankBT / NT Series

ER R8 Taper ShankBT / NT Series

ER Jacobs Female Taper ShankBT / NT Series

ER Jacobs Female Taper ShankBT / NT Series

MER Spring Collet ChuckBT / NT Series

MER Spring Collet ChuckBT / NT Series

ERA High Speed Collet ChuckBT / NT Series

ERA High Speed Collet ChuckBT / NT Series

ERA Nut & WrenchBT / NT Series

ERA Nut & WrenchBT / NT Series

ER Spring ColletBT / NT Series

ER Spring ColletBT / NT Series

ER Collet for End MillBT / NT Series

ER Collet for End MillBT / NT Series

ER Collet - Coolant TypeBT / NT Series

ER Collet - Coolant TypeBT / NT Series

ER-GB Tap ColletBT / NT Series

ER-GB Tap ColletBT / NT Series

ER Spring Collet SetBT / NT Series

ER Spring Collet SetBT / NT Series

ER Spring Collet SetBT / NT Series

ER Spring Collet SetBT / NT Series

ER Clamping NutBT / NT Series

ER Clamping NutBT / NT Series

ER Clamping NutBT / NT Series

ER Clamping NutBT / NT Series

ER Clamping NutBT / NT Series

ER Clamping NutBT / NT Series

Advantages of High Speed Collet Chucks #

High speed collet chucks deliver several benefits compared to traditional tool holding solutions:

- Optimized for High Speed and Precision: Special designs enable these chucks to perform reliably at high speeds while maintaining accuracy.

- Reduced Vibration: For example, the ADS Collet Chuck Series features a nutless design that minimizes cutting vibration, making it ideal for small diameter work and providing superior tool clearance and grip force.

- Enhanced Clamping Force and Rigidity: The AVC Collet Chuck Series uses an 8° long type collet and a thick shank design to increase clamping force, cutting rigidity, and precision.

- Low Profile for Close Machining: The compact design allows machining operations to occur very close to the workpiece.

- Consistent Grip at High Speeds: Collet chucks are less affected by centrifugal force, ensuring stable grip force even during high-speed operations.

Collet chucks are indispensable in modern machining, offering a combination of precision, efficiency, and versatility. Ann Way’s comprehensive selection is designed to meet the diverse needs of machining professionals, ensuring reliable and accurate tool clamping for optimal performance.

For more information or to discuss specific requirements, contact us at any time.